| How to maintain knitting machine |

| Hits:2347 AddTime:2020/10/5 9:27:12 |

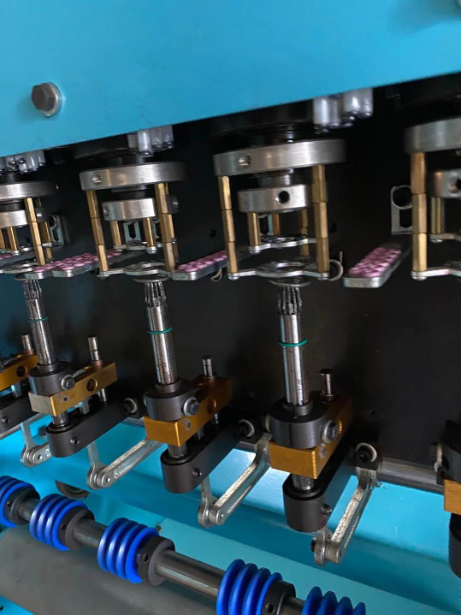

Jiangsu xiangdao Precision Machinery Co., Ltd. is an industrial enterprise focusing on R & D, manufacturing, sales and service of high-speed knitting machine series equipment and surrounding supporting equipment. The company is located in Shanghai, the international capital, and has Jiangsu Dongtai high-speed knitting machine production base. The company covers a total area of 30000 square meters, and the existing construction area is 15000 square meters. There are two phases of planning The construction area is 10000 square meters.

Xiangdao company is one of the manufacturers with large production scale, professional production equipment, strong technology and productivity. The company is an entity manufacturer with high self-supporting ability of spare parts, and is a manufacturer that comprehensively masters the independent production process of all core parts of high-speed knitting machine, so as to ensure long service life.

2. At least once per shift to ensure that the moving parts have enough flexibility, so as to avoid abnormal thermal wear of the speed driving part and reduce the service life of the equipment.

4. Knitting machine to timely abnormal parts, to ensure the quality of production. 5. Tighten each screw and nut of the equipment regularly to ensure the stability of operation, so as to avoid abnormal sound and living equipment. 6. Properly control the frequency converter output frequency, so as not to affect the life of the equipment. 7. The chain is lubricated to prevent the oil from entering into the tension of the friction plate, resulting in the friction plate slipping and affecting the coiling frame.

|

| 【Refresh】【Favorites】【Print】 【Close】 |

| Previous:What should be done when assembling automatic knitting machine Next:Maintenance measures of fasteners for knitting machine |